Coalescing Filters and Filter Separators: Used and Surplus

Surplus Energy Equipment (SEE) has formed many business relationships with surplus equipment brokers and used oilfield equipment suppliers to have a more extensive inventory to meet our customers’ unique requests.

If you have oil and gas processing equipment that you would like to sell, you can get started on selling your used gas equipment on the Surplus Energy Equipment platform.

We are going to specifically focus on used filter separators and coalescing filters for the separation of contaminants.

What is a Gas Filter Separator?

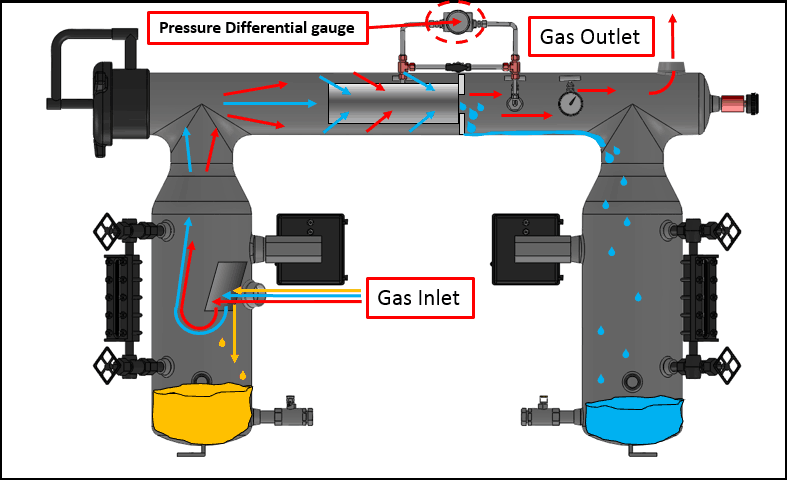

Filter Separators are designed to remove heavy mist and particulates from the gas stream. They are designed to use a filter element, typically 1-10 microns, that can catch the particulates and coalesce some large droplets in the gas stream. These vessels are usually in a horizontal configuration to make change out of the filters easier and can have either no-sump, one-sump, or dual-sump liquid collection sections. Depending on what you want to remove from the gas will determine if you should use a filter better suited for dry particulates, liquids, or a combination of both.

What is a Gas Coalescing Filter?

Gas Coalescing Filters are designed to remove mist, fog, and dust from the gas stream. They are designed to use a filter element, typically 0.3-1 micron, that can coalesce, or bring together, smaller droplets of aerosols or mist into larger droplets that can be then separated by gravity. They will also collect particulates, especially with such a small micron rating, but are designed for aerosols. Coalescing Filters are typically in a vertical configuration to optimize for filter drainage of the coalesced liquids. A vertical configuration is typically needed to get an absolute 0.3-micron performance out of your filters. Coalescing filters are recommended ahead of gas processing equipment such as amine plants, dehydrators, and cryogenic units, especially if the gas is rich and potential cooling can cause condensation of the heavy hydrocarbons.

What to look for when buying a filter separator or coalescing filter.

In buying a coalescing filter, the areas of concern are the integrity of the vessel, the mating face of the enclosure, and the internals for the filter/filter plate. Gas In/Out flanges are an excellent way to get an idea of the capacity of a vessel. Still, the filter’s capacity will be determined by the gas quality and the contaminants you are trying to remove. Determining the micron size and composition of your contaminant is essential because these contaminants are usually smaller than 10 microns and the filter vessel and filter to use are critical to ensure good operation. For example, if your issue is foaming in a dehydrator due to detergent in your compressor oil, then a filter separator will not do much to remove these contaminates. Likewise, an excellent reverse flow vertical coalescing filter will only be able to remove a little aerosol or mist with cheaper particulate filters installed.

The differential pressure across the filter will rise as the filter collects contaminants. Filters should be changed when the differential reaches 10-15 PSI.

Buy parts for a coalescing filter.

Sell your used coalescing filters for sale.