Buying Used Reboilers and Regens

Surplus Energy Equipment (SEE) wants the people that view its equipment to be educated on what to look out for when purchasing used oilfield equipment. The purpose of this blog is to review some highlights and key characteristics of used reboiler and regen equipment.

What is a reboiler?

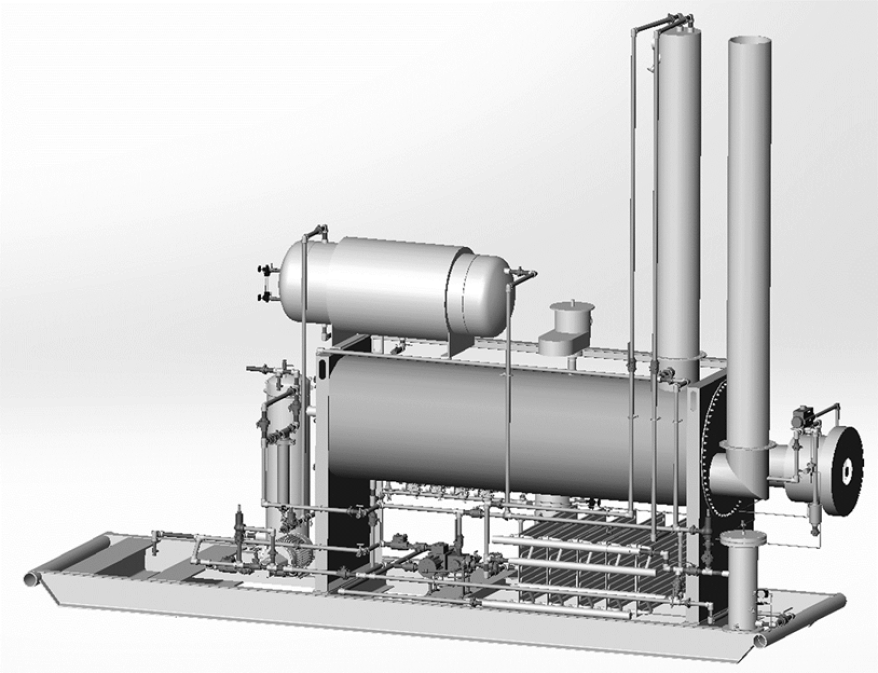

A reboiler is essentially a direct-fired or steam-heated element to regenerate rich amine or glycol to lean amine or lean glycol. Reboilers are used in an amine plant or dehydration equipment. The words, ‘reboiler’ and ‘regen’ may be used interchangeably, but a reboiler is a part of a regen skid.

A regen in amine use will flash off acid gases H2S and CO2 and circulate water-saturated amine to the reboiler. When purchasing a regenerative system, you will want to check all the major components included, and that they can pass an integrity check:

Flash Tank: Helps hydrocarbons to flash. Hydrocarbons are removed because they often promote foaming.

Reboiler: Burns off excess liquid water saturated in amine or glycol, and turns water into vapor aiding to break the bond amine has with H2S and CO2 and glycol with water.

Optional BTEX unit in TEG use: Water vapors released by the reboiler are condensed through the BTEX unit and all of the other gas compounds, not condensed are injected to the reboiler burner to be eliminated.

Filters: Removes particulates and purifies the amine or glycol.

Pumps: Used to circulate amine or glycol in and out of the regenerative system.

If you would like to purchase a surplus or used regens off the website but would like to have it reconditioned or tested, that service can be conducted as well through our service partner, Croft Production Systems.

Need to buy parts for a reboiler and a regen click here.

If you have any used reboilers and regens for sale click here.

If you like to buy a used reboilers or regens click here.